Beads in construction are also both for the look and the feel; they act as ornaments and guards all at the same time. With its flexibility in application when used this element would change the ordinary building structures’ aspects into aesthetic and sturdy ones. Regardless of whether the bead is being applied to edges of the wall, or on frames of doors or windows, or in furniture or cabinets, it holds quite a large rank in construction. It is understood to refer to the strength of structural shapes in terms of load carrying capability, this section examines its meaning, applications, types, and implications on the strength of building structures.

What is Beading in Construction?

Battening in construction is the use of a narrow member such as wooden, metal, or PVC strip along the edges of walls, door or on the corners. They are mainly used for aesthetic purposes although they offer a measure of security since it strengthens weak points in a building such as corners, joints and edges.

Types of Beading in Construction

Beading is classified into two primary categories: decorative and functional.

Decorative Beading

Decorative beading enhances the visual appeal of building features by adding stylish, rounded edges. It can be applied in various areas of a building to create an elegant and cohesive look.

Applications of Decorative Beading:

- Doors and Windows:Wooden beading for door frames or window frames adds a polished, classic touch. For example, intricately carved wooden beading in traditional Indian homes highlights craftsmanship and provides an artistic flair.

- Flooring: They used Wooden wall beading to fill voids in walls and floor joints to make the work neat and avoid the likelihood of dirt collection.

- Furniture: Interior finished with beads on doors,drawers,shelves etc turns simple furniture into luxurious furniture pieces as they demonstrate workmanship.

Functional Beading

These beading patterns have functional uses such as filling up joint spaces, offering protection or as a way of allowing material to expand or contract.

Applications of Functional Beading:

- Walls: Contour metallic molding helps guard corners in zones of heavy traffic like educational complexes or offices against chips or other kinds of damage.

- Furniture: Plastic edge beading helps furniture edges not to chip hence they should work for quite a while.

- Tiles: Beadings around the tiles prevent chipping on edges; especially if applied in areas that are sensitive to moisture such as in kitchens and bathrooms.

- Concrete Structures: On the concrete joints, the use of rubber beading helps in flexing in cases of high temperatures and low temperatures in hope of avoiding the appearance of the cracks.

- Roofing: Steel pop-up beadings hold roofing tiles and eradicates the issues of sagging roofs and the need for replacement for a very long time.

How Beading Enhances Wall Strength

While beading doesn’t directly add structural strength, it contributes indirectly by:

- Protecting Corners: Angle beads shield corners, preventing damage and maintaining structural integrity.

- Allowing Flexibility: Expansion beads in drywall construction accommodate slight movements, reducing the risk of cracks that weaken walls.

Beading vs. Molding vs. Trim

Though often confused, beading, molding, and trim have distinct features:

| Feature | Beading | Molding | Trim |

| Size | Narrow strip | Wider, varying shapes | Can vary widely |

| Profile | Rounded | Rounded, flat, or complex | Flat, rounded, or decorative |

| Purpose | Decorative or functional | Decorative | Decorative and functional |

| Applications | Wall beading, door side beading | Archways, ceilings, door frames | Transitions, baseboards, casings |

| Materials | Wood, metal, PVC | Wood, MDF, plaster | Wood, PVC, plaster |

Key Difference: Beading often has a simpler profile and dual functionality, while molding and trim focus more on aesthetics.

Common Materials for Beading

Beading materials vary based on application:

- Wood: Ideal for traditional or decorative purposes like beading for door frames and furniture.

- PVC (Plastic): Commonly used in modern interiors for its durability and resistance to moisture.

- Metal: Suitable for high-traffic areas where durability is essential, such as sheet metal beading.

- Aluminum and Steel: Often used for structural support in roofing and bridges.

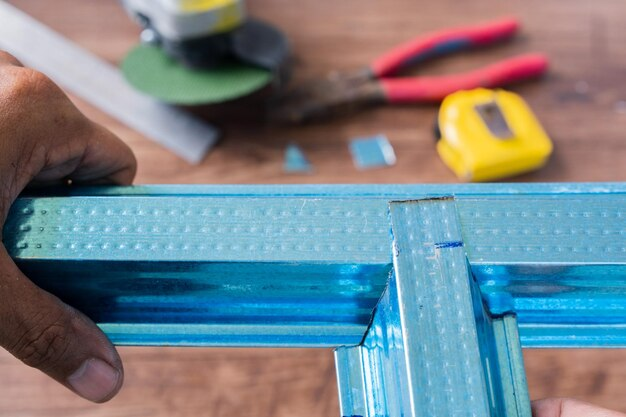

Beading Installation Process

- Measurement: Accurately measure the area where beading will be applied.

- Cutting: Cut the beading to the required length using a saw or appropriate tool.

- Fixing: Secure the beading with nails, screws, or adhesive based on the material and surface.

- Finishing: Paint or varnish the beading to match the surrounding surfaces for a cohesive appearance.

Beading in Construction Applications

Beading is versatile and can be used in:

- Walls: For wallpaper beading and decorative trims.

- Doors and Windows: Enhancing aesthetics and securing glass panels.

- Roofing: Providing stability and preventing sagging in roof structures.

Conclusion

Beading in construction combines aesthetics with functionality, offering solutions that enhance the beauty and durability of building components. Whether it’s beading wall design, door side beading, or white beading for modern interiors, its applications are endless. At Wallsanddreams you can choose the right material and type, beading can elevate the overall design and ensure lasting protection for your construction project.