With the advancement of PUF panels in recent years, the technology has transformed the world of building into energy efficient, lightweight and cost effective buildings. It can be a small PUF sheet house, or a big cold storage unit in the industry, the use of PUF panels is taking Residential, Commercial, and Industrial by a storm. This blog will discuss what PUF panels are and their components, types, properties as well as their price. It will also enable you to realize the various applications of various forms of PUF as the wall panels of PUF, panel sheets of PUF, and partition of PUF in the construction industry today.

What is a PUF Panel?

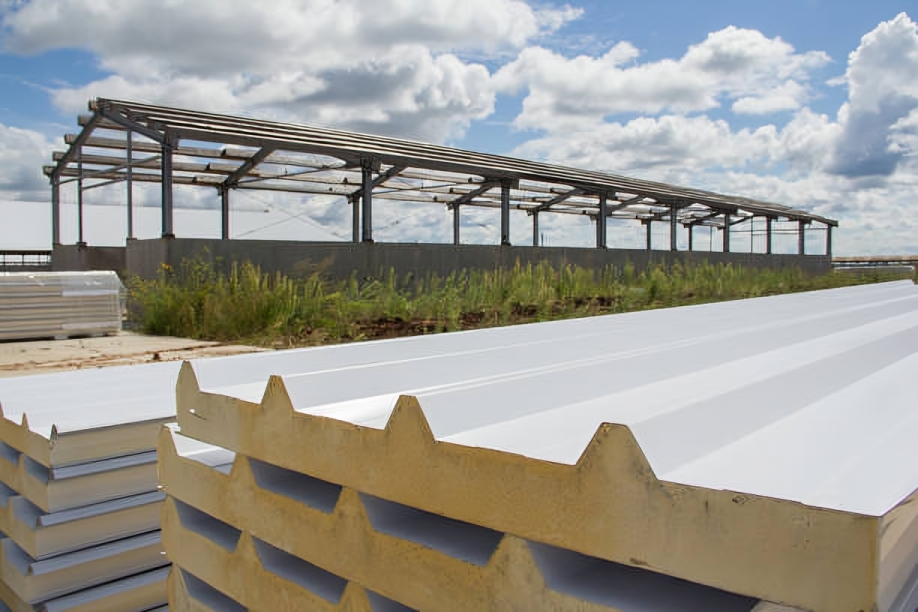

PUF panel is an abbreviation of Polyurethane Foam Panel. The full form of PUF (polyurethane foam) explains the construction of the material. The material is a thermal insulation polyurethane foam sandwiched between two sheets of metal. Typically these layers consist of galvanised iron (GI), aluminium or stainless steel.

PUF panels are created in the factory and assembled on-site, which makes them very efficient time and labour-wise. PUF panels are quite extensively used in constructing building walls, ceilings, and even buildings entirely out of PUF panel rooms or cabins based on their thermal and acoustic insulation properties.

Main Components of PUF Panel

An example of a PUF panel is some three main elements:

1. Outer Skin (Metal Face Sheet):

This is normally constructed of GI, aluminum or pre-painted galvanized iron (PPGI).. It secures the core of foam and gives mechanical strength.

2. Insulating Core (PU Foam):

Rigid polyurethane foam is used as the core and it provides a superior thermal performance.

3. Adhesive Layer:

This secures the core foam to the exterior metal skins, and secures the structure.

It does not matter whether it is a PUF wall panel, roof panel, or ceiling unit, they all have three basic layers which form a sandwich type of structure.

Types of PUF Panels

The PUF panels come in various forms suitable to a variety of applications. Some of them are common like:

1. PUF Wall Panel

PUF wall panels being specifically designed to be installed vertically find application in warehouses, cold storages, and industrial enclosures. They are great insulators and they can resist fire to some degree.

2. PUF Panel Partition

These can be utilized in large spaces when one needs to divide it into smaller rooms or sections without otherwise constructing brick and mortar structures. PUF panel partitions can be applied anywhere such as temporary offices, modular toilets, or workshop cabins.

3. PUF Sheet for Roofing

A PUF sheet finds its major application in industries as a roofing system mainly applied on buildings, poultry farms, and temporary dwellings. It has great thermal insulating properties and it is weather proof.

4. PUF Panel Room

This means a whole room constructed by PUF panels. The applicability of PUF panel rooms is in the cleanrooms, security cabin, and mobile offices. Such rooms are pre-fabricated hence simple to install and move around.

5. PUF Sheet House

A PUF sheet house is a perfect choice when considering affordable housing options, particularly where the housing needs are remote. These houses are light built, insulated and are easily customized. They are also effective even in extreme climates.

Properties and Advantages of PUF Panels

PUF panels offer several distinct advantages over traditional construction materials:

1. Excellent Thermal Insulation

The closed-cell composition of PUF restricts the movement of heat, making it an ideal product to use in a temperature-sensitive area such as cold storage or home in extreme climates.

2. Lightweight and Durable

PUF panel sheets are much stronger than light and can resist wear and tear due to mechanical impacts.

3. Fire-Resistant

To enhance security, the fire-retardant chemicals can be impregnated into the PUF panels.

4. Eco-Friendly and Energy Efficient

There is less heating or cooling and this is in the context of a lower consumption of energy and in this regard, the walls that are made out of PUF panels are a green solution.

5. Fast and Easy Installation

As panels are prefabricated, the construction time is increased significantly.

6. Acoustic Insulation

Puff panelling also has good sound insulation benefits, so is suitable for office, studio or meeting room areas.

PUF Full Form and Common Misconception

Although the panels are commonly called as PUFF panels by a majority of the people, their actual name is PUF and this short form means Polyurethane Foam. Puff panelling is the commonly used phrase, but in technical and correct terms it is PUF panelling.

Applications of PUF Panels

PUF panels are flexible and they are applied in:

- Cold storages

- Modular offices

- Industrial enclosures

- Portable cabins

- Prefabricated homes

- Poultry farms

- Mobile toilets

- Cabins of security guards

- Telecom shelters

As an example, the construction of PUF sheet houses in rural or disaster-prone regions is fast and cost effective. Equally, using a PUF panel partition, a single hall can be transformed into several usable workstations.

PUF Panel Price in India

In India, the cost of PUF panels will be different and will be affected by a number of factors:

- Thickness (usually 40mm through 150mm)

- Sheet material (GI, PPGI, Aluminum)

- Using it (refrigeration wall, roof, cold room)

- Personalizations (fire retardant, color coated, etc.)

Currently, PUF panel prices in India can be found at a rate as high as 1,000 to 1,800 rupees per square meter by the year 2025. Specialty panels (like PUF wall panels as cold storage) or those thicker ones might be more costly.

There are also the PUF sheet prices that are based on the brand and the volumes of the order. When looking into large-scale construction, purchasing at large quantities can reduce unit cost.

Conclusion

The increase in demand of PUF panels is not unexpected because it has the highest level of thermal insulation, labor-efficient installation process, affordable price and environmental-friendly properties. PUF panels offer versatile solutions to different needs whether you require them to roof your building, insulate your wall, or even construct a whole room of PUF panel infrastructure.

In case of your future construction, you should think about incorporating PUF panel partitions, walls or roof to increase efficiency and comfort. Whether it is the humble PUF sheet house or the complex cold room, the application of PUF panelling is reaching all sorts of places quickly, thereby showing that intelligent construction need not be costly or complex.